Coated Abrasives Market Size, Share, Growth and Forecast to 2032

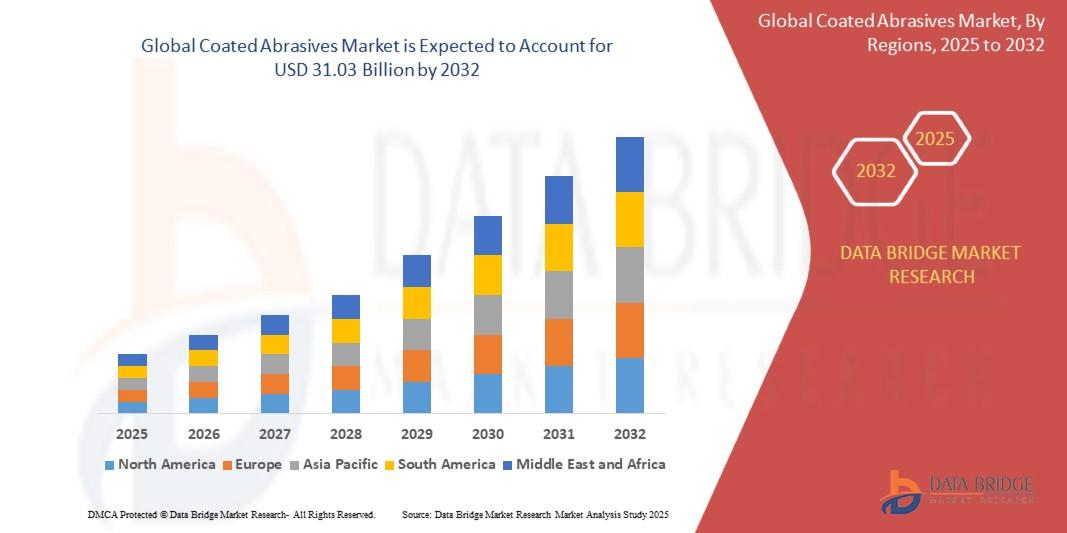

The Coated Abrasives Market is steadily advancing. Valued at USD 20.37 billion in 2024, the market is projected to reach USD 31.03 billion by 2032, growing at a compound annual growth rate (CAGR) of 5.4% from 2025 to 2032. This article provides a comprehensive analysis of market dynamics, segmentation, drivers, challenges, and competitive insights, drawing exclusively from Data Bridge Market Research to guide stakeholders in this essential sector.

What Are Coated Abrasives?

Coated abrasives consist of abrasive grains (e.g., aluminum oxide, silicon carbide) electrostatically adhered to a backing material (e.g., cloth, paper) via bonding agents, forming products like belts, discs, and rolls. They excel in material removal, surface preparation, and finishing, supporting automated processes in manufacturing. Globally, advancements in bonding technologies and sustainable formulations are addressing environmental concerns while meeting demands for precision in electric vehicle production and construction.

Market Size and Growth Projections

The global coated abrasives market is buoyed by industrial expansions and technological upgrades, with North America leading due to its robust manufacturing base. The base year is 2024, with forecasts extending through 2032, reflecting a shift toward high-performance, eco-friendly variants.

| Year/Period | Market Value (USD Billion) | CAGR (%) |

|---|---|---|

| Base Year (2024) | 20.37 | - |

| Forecast (2025–2032) | Projected to 31.03 by 2032 | 5.4 |

North America dominates the market, driven by demand in automotive and aerospace, while Asia-Pacific is the fastest-growing region, fueled by rapid industrialization in China and India.

Market Segmentation

The market is meticulously segmented to uncover growth opportunities:

By Product Type

- Belts: Expected to dominate with 30-35% share in 2025, ideal for high-volume applications in metalworking, automotive, and woodworking.

- Discs: Projected to account for 25-30% share in 2025, favored for precision grinding and polishing in automotive and electronics.

- Rolls: Versatile for continuous processes.

- Sheets: Common for manual finishing.

- Others: Including specialized formats.

By Material Type

- Aluminium Oxide: Widely used for general-purpose grinding.

- Silicon Carbide: Preferred for hard materials like ceramics.

- Zirconia Alumina: High-performance for heavy-duty tasks.

- Ceramic Alumina: Emerging for durability.

- Other Material Type: Hybrid innovations.

By Backing Material

- Cloth: Dominant for flexibility in belts and rolls.

- Paper: Cost-effective for sheets and discs.

- Fiber: Robust for industrial applications.

- Polyester: Growing for strength and tear resistance.

- Other Backing Material: Sustainable alternatives.

By End-Use Industry

- Construction: Largest segment, driven by infrastructure projects.

- Woodworking: For finishing and shaping.

- Automotive: Key for bodywork and parts preparation.

- Aerospace: Precision demands.

- Metal Working: For welding and grinding.

- Other End-Use Industries: Including electronics and furniture.

By Region

- North America: U.S., Canada, Mexico—strong in advanced manufacturing.

- Europe: Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey—focus on automotive.

- Asia-Pacific: China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines—fastest growth.

- Middle East and Africa: Saudi Arabia, U.A.E., South Africa, Egypt, Israel.

- South America: Brazil, Argentina.

Download Full Report Here : https://www.databridgemarketresearch.com/reports/global-coated-abrasives-market

Key Drivers Fueling Growth

- Technological Advancements: Innovations in grains like ceramic and zirconia, along with improved bonding agents and automated production, enhance efficiency and longevity.

- Industrial Demand Surge: Rising needs in automotive, aerospace, and construction for precision surface finishing.

- Specialized Applications: Development of abrasives tailored for sanding automotive parts and polishing metals.

Challenges and Restraints

- High Manufacturing Costs: Specialized materials, techniques, and quality controls make advanced abrasives expensive, limiting accessibility in price-sensitive markets, especially in developing regions.

Opportunities

- Eco-Friendly Innovations: Demand for sustainable, biodegradable abrasives using natural fibers and resins to meet environmental regulations in automotive and construction.

- Emerging Economy Growth: Industrialization and infrastructure development in Asia-Pacific and other regions.

Competitive Landscape

The market is competitive, featuring global leaders focused on collaborations and launches:

- Saint-Gobain Abrasives (France): Launched the Norton Abrasive Process Solutions (APS) Program in April 2022 for optimizing grinding and finishing, including access to machines at the Higgins Grinding Technology Center in Northborough, Massachusetts.

- 3M (U.S.): Collaborated with AV&R (Canada) in May 2023 to develop robotic systems (BF-X 200-c and TF-X 1200) for automating surface finishing, announced at the Automate show in Detroit on May 23, 2023.

- Tyrolit Group (Austria)

- Carborundum Universal Limited (India)

- Sia Abrasives Industries AG (Switzerland)

- Mirka (KWH Group) (Finland)

- Bosch Limited (Germany)

- Höganäs AB (Sweden)

Future Trends and Opportunities

By 2032, the market will pivot toward high-performance abrasives for electric vehicle production, including battery components and bodywork, with low-temperature, high-efficiency options from companies like 3M and Saint-Gobain. Trends include eco-friendly adhesives like water-based and solvent-free variants, alongside automation for cost efficiency. Opportunities in sustainable formulations and emerging markets will align with global green initiatives.

Conclusion

The Global Coated Abrasives Market is set for consistent expansion to USD 31.03 billion by 2032 at 5.4% CAGR, balancing industrial demands with innovative, sustainable solutions. Stakeholders should address cost barriers through eco-innovations to capitalize on opportunities in automotive and Asia-Pacific. Prioritizing North America's infrastructure and global tech advancements will ensure a sharp competitive edge.

Browse More Reports:

Global Peptide Supplements Market

Global Women’s Health Rehabilitation Products Market

Global Polyethylene Terephthalate (PET) Bottle Market

Global Functional Apparel Market

Asia-Pacific Superhydrophobic Coating Market

Middle East and Africa Indoor LED Lighting Market

Europe Construction Robot Market

Middle East and Africa Alkyd Resin Market

Global Risk Management Market

Global Grease Market

Global Fertility Services Market

Global Tunnel Boring Machine Market

Global Invisible Orthodontics Market

Global Ready to Drink Tea and Ready to Drink Coffee Market

Global Triazole Fungicides Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness