-

Новости

- ИССЛЕДОВАТЬ

-

Страницы

-

Группы

-

Мероприятия

-

Статьи пользователей

-

Marketplace

-

Offers

-

Jobs

-

Courses

-

Игры

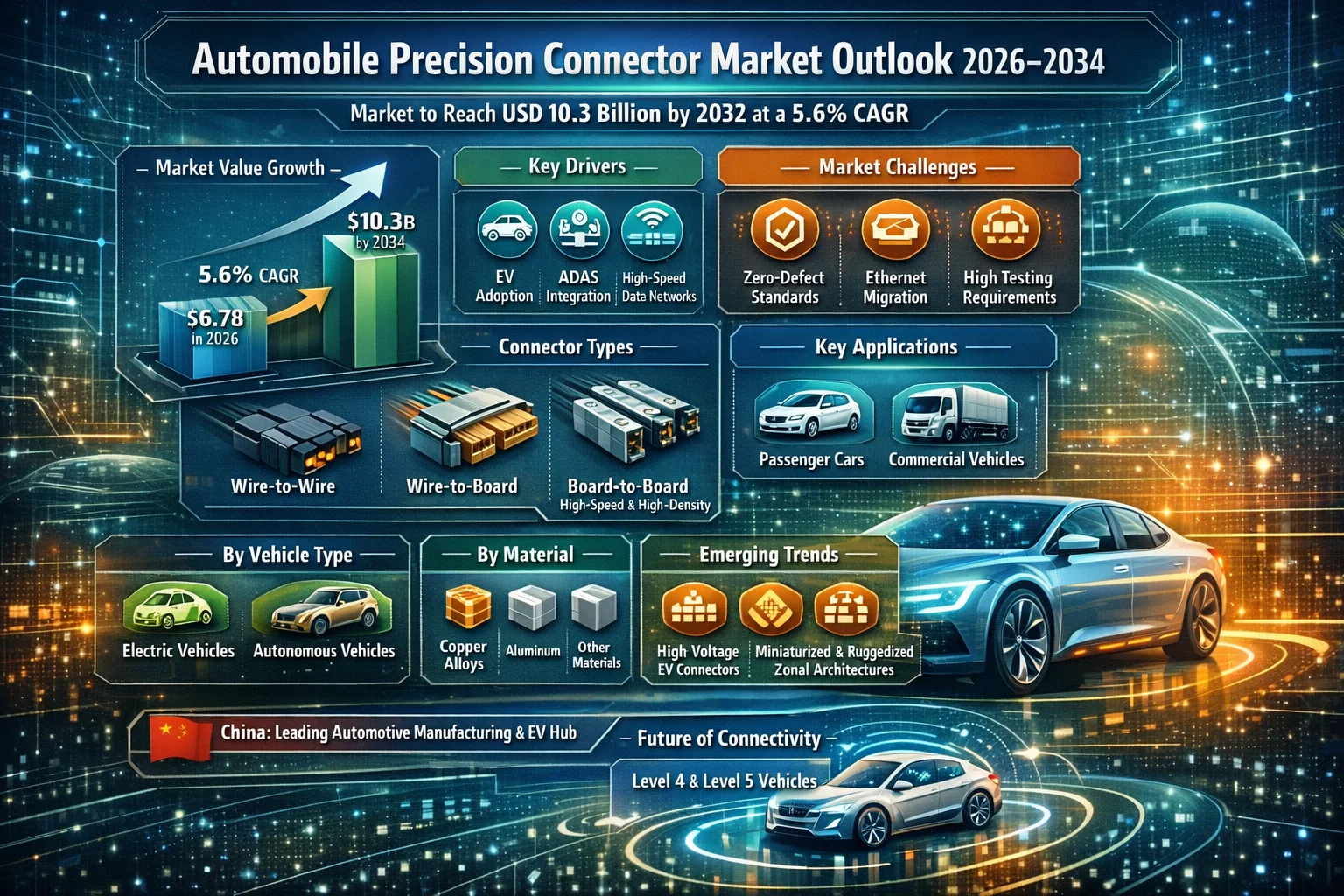

Automobile Precision Connector Market to Reach USD 10.3 Billion by 2034 at a CAGR of 5.6%

global Automobile Precision Connector Market size was valued at USD 6.78 billion in 2026 and is projected to reach USD 10.3 billion by 2034, at a CAGR of 5.6% during the forecast period 2026–2034. Growth is being fueled by accelerating vehicle electrification, rising ADAS integration, and the shift toward high-speed in-vehicle data networks across passenger and commercial platforms.

Automotive precision connectors are specialized components that establish secure electrical connections between circuits in vehicles. These connectors ensure reliable signal transmission and power distribution across infotainment, safety, body electronics, and powertrain systems. The market primarily includes wire-to-wire, wire-to-board, and board-to-board connector variants designed for vibration resistance, thermal stability, and long lifecycle performance.

👉 Full report access with detailed forecasts and competitive analysis:

https://semiconductorinsight.com/report/automobile-precision-connector-market/

Market expansion is strongly linked to increasing electronic content per vehicle and the rapid deployment of ADAS features such as radar, cameras, LiDAR, and centralized compute units. Passenger cars accounted for about 72% of total demand in 2024, supported by high production volumes and feature-rich architectures, while commercial vehicles are showing faster adoption of rugged, high-performance connector systems. Asia-Pacific leads globally with the largest revenue share, supported by China’s dominant automotive manufacturing base and EV production scale.

Market Challenges

Quality and reliability requirements are intensifying as connectors become safety-critical components. Failures in braking, steering, or ADAS connectors carry severe risk, prompting OEMs to enforce zero-defect standards and extensive validation regimes — often exceeding 500 qualification tests per connector family. This significantly increases development cost and time while requiring advanced simulation, materials engineering, and automated test infrastructure.

Technology migration toward Ethernet-based vehicle architectures and zonal electrical systems introduces redesign and certification burdens. Suppliers must support legacy platforms while investing in next-generation high-speed and high-density connector portfolios, creating portfolio and capital allocation pressure.

Market Opportunities

Autonomous and software-defined vehicle platforms present major upside potential. Level 4 and Level 5 vehicles may require three to five times more connectors than conventional vehicles to support distributed sensors, redundant control paths, and high-bandwidth compute modules. These use cases demand miniaturized, shielded, and ruggedized connectors capable of maintaining signal integrity at multi-gigabit data rates under harsh automotive conditions.

Connector innovation is also accelerating around high-voltage EV systems, lightweight conductive materials, and modular zonal harness architectures that reduce wiring complexity and vehicle weight.

Key Automobile Precision Connector Companies Profiled

- TE Connectivity (Switzerland)

- Yazaki Corporation (Japan)

- Aptiv (Ireland)

- Amphenol (U.S.)

- JST (Japan)

- Molex Incorporated (U.S.)

- Sumitomo (Japan)

- Shanghai Laimu Electronics (China)

- JAE (Japan)

- KET (Korea Electric Terminal) (South Korea)

Segment Analysis: By Type

- Wire-to-Wire Connector

- Wire-to-Board Connector

- Board-to-Board Connector

- Subtypes: High-speed, High-density, Standard

- Others

Wire-to-wire connectors lead in volume due to design simplicity, cost efficiency, and broad harness usage across vehicle subsystems.

Segment Analysis: By Application

- Passenger Cars

- Commercial Vehicles

Passenger cars dominate demand due to higher global production and rapid feature integration.

Segment Analysis: By Material

- Copper Alloys

- Aluminum

- Other Conductive Materials

Copper alloys remain preferred for conductivity, corrosion resistance, and mechanical durability.

Segment Analysis: By Vehicle Connectivity

- Conventional Vehicles

- Electric Vehicles

- BEV, PHEV, HEV

- Autonomous Vehicles

Conventional vehicles still account for the majority of shipments, but EV and autonomous segments are expanding connector value per vehicle.

Regional Outlook

North America benefits from advanced automotive R&D, ADAS deployment, and EV platform investments, with strong demand for high-speed data connectors. Europe’s market is driven by premium vehicles, strict standards such as ISO 8092 and LV214, and rapid high-voltage EV rollout aligned with combustion phase-out targets. Asia-Pacific remains the largest production and consumption hub, supported by large-scale vehicle manufacturing and aggressive electrification programs.

👉 Full report access with detailed forecasts and competitive analysis:

https://semiconductorinsight.com/report/automobile-precision-connector-market/

📄 Download the free sample report here:

https://semiconductorinsight.com/download-sample-report/?product_id=103110

About Semiconductor Insight

Semiconductor Insight is a global intelligence platform delivering data-driven market insights, technology analysis, and competitive intelligence across the semiconductor and advanced electronics ecosystem. Our reports support OEMs, investors, policymakers, and industry leaders in identifying high-growth markets and strategic opportunities shaping the future of electronics.

🌐 https://semiconductorinsight.com/

🔗 LinkedIn: Follow Semiconductor Insight

📞 International Support: +91 8087 99 2013

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness