Advancements in Rubber Compounding Fuel Growth of Rubber Processing Chemicals Market

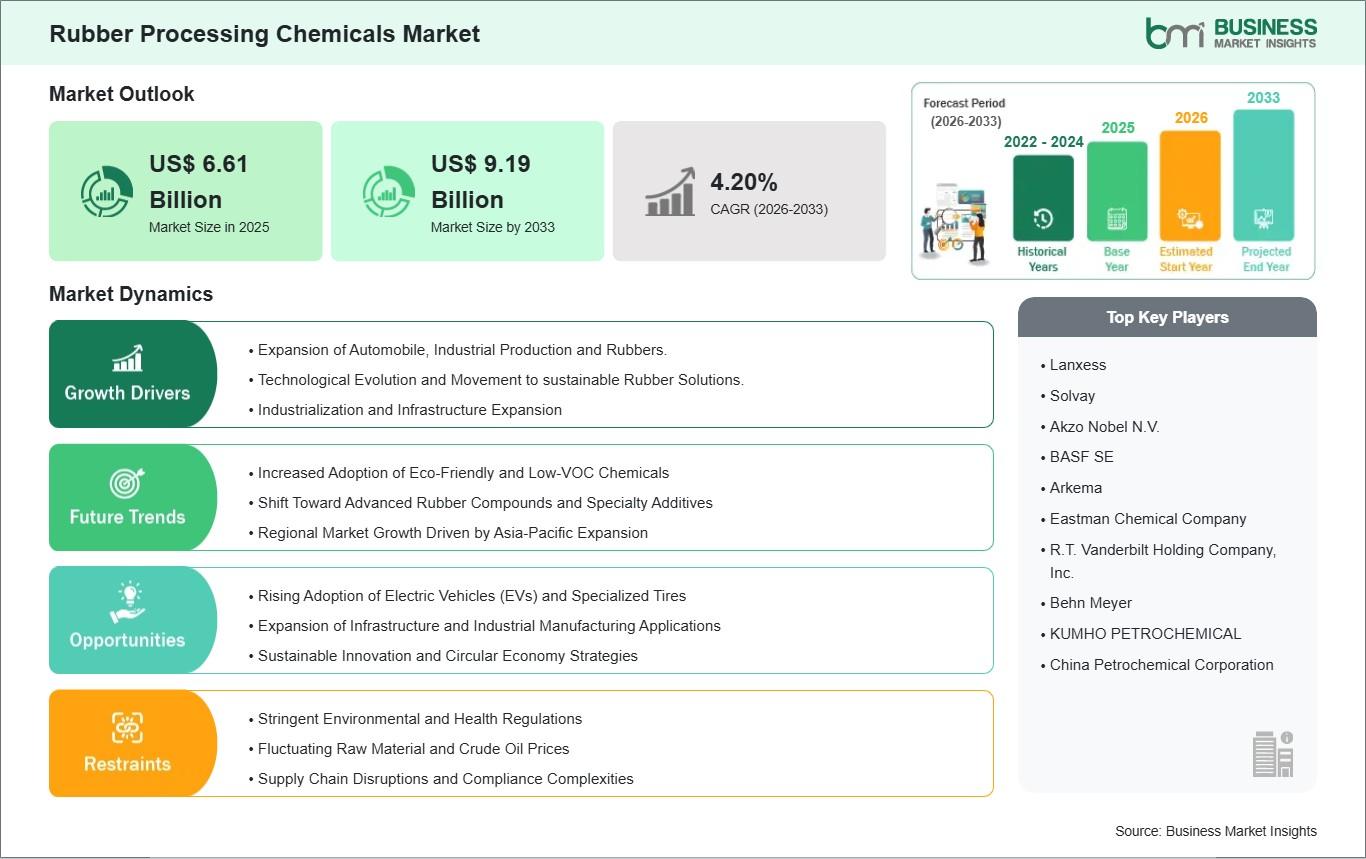

The Rubber Processing Chemicals Market is experiencing steady expansion as global demand for high-performance rubber products continues to rise across automotive, industrial, and consumer applications. Rubber processing chemicals play a critical role in enhancing the durability, flexibility, safety, and performance of rubber compounds during manufacturing and end-use. As rubber remains an indispensable material in tires, industrial components, and non-tire applications, the importance of specialized processing chemicals is becoming increasingly prominent.

Rubber processing chemicals are used to improve processing efficiency, extend product lifespan, and ensure compliance with safety and quality standards. With advancements in rubber formulation technologies and growing emphasis on sustainable and high-efficiency materials, the Rubber Processing Chemicals Market is positioned for sustained growth over the coming years.

Market Overview

The Rubber Processing Chemicals Market is expanding due to rising production of tires and non-tire rubber products, particularly in automotive and industrial sectors. Tires account for a significant share of global rubber consumption, driving consistent demand for processing chemicals such as accelerators, anti-degradants, and processing aids. These chemicals help improve vulcanization efficiency, enhance resistance to heat and oxidation, and optimize manufacturing performance.

In addition to tires, non-tire applications—including hoses, belts, seals, gaskets, footwear, and industrial rubber goods—are contributing to market growth. Increasing infrastructure development, industrialization, and consumer demand for durable rubber products are reinforcing the need for advanced rubber processing solutions.

Key Market Drivers

Several factors are supporting the growth of the Rubber Processing Chemicals Market:

Rising global vehicle production and replacement tire demand

Expanding industrial and infrastructure development activities

Growing use of rubber components in automotive and manufacturing sectors

Increasing focus on performance, safety, and durability of rubber products

Continuous innovation in rubber compounding and processing technologies

Manufacturers are increasingly adopting advanced processing chemicals to meet evolving regulatory standards and improve product efficiency, further boosting market demand.

Type-Based Market Insights

Based on type, the Rubber Processing Chemicals Market is segmented into anti-degradants, accelerators, flame retardants, processing aids/promoters, and others. Anti-degradants hold a significant share as they protect rubber products from degradation caused by heat, oxygen, ozone, and environmental stress, thereby extending product life.

Accelerators are essential for controlling the vulcanization process, enabling faster curing and improved physical properties of rubber compounds. Flame retardants are gaining traction in applications where fire resistance and safety are critical, particularly in industrial and construction-related rubber products. Processing aids and promoters play a key role in improving material flow, reducing energy consumption, and enhancing manufacturing efficiency.

Application-Based Analysis

By application, the Rubber Processing Chemicals Market is broadly categorized into tire and non-tire segments. The tire segment dominates the market, supported by continuous demand from passenger vehicles, commercial vehicles, and off-road applications. Tire manufacturers rely heavily on processing chemicals to achieve optimal performance characteristics such as traction, durability, and fuel efficiency.

The non-tire segment is witnessing steady growth, driven by rising demand for rubber components used in industrial machinery, construction equipment, consumer goods, and healthcare products. Non-tire applications require specialized rubber formulations, further supporting the adoption of a wide range of processing chemicals.

Regional Outlook

From a regional perspective, Asia Pacific represents the largest and fastest-growing market for rubber processing chemicals. The region benefits from strong automotive manufacturing bases, expanding industrial activities, and rising infrastructure investments. Countries such as China and India are major contributors due to large-scale tire production and increasing domestic demand for rubber goods.

North America and Europe are mature markets characterized by technological advancements, stringent regulatory frameworks, and a strong focus on high-performance and sustainable rubber solutions. These regions emphasize innovation, quality, and compliance, driving demand for advanced processing chemicals.

Latin America, the Middle East, and Africa are emerging markets, supported by growing automotive industries, infrastructure development, and increasing industrialization. As manufacturing capabilities expand in these regions, demand for rubber processing chemicals is expected to rise steadily.

Competitive Landscape and Key Players

The Rubber Processing Chemicals Market is moderately competitive, with global and regional players focusing on product innovation, capacity expansion, and strategic collaborations. Key companies operating in the market include Lanxess, Solvay, Akzo Nobel N.V., BASF SE, Arkema, Eastman Chemical Company, R.T. Vanderbilt Holding Company, Inc., Behn Meyer, and KUMHO PETROCHEMICAL.

These market leaders are investing in research and development to enhance chemical performance, improve sustainability, and address evolving customer requirements. Strategic partnerships, acquisitions, and expansion into emerging markets are common strategies used to strengthen competitive positioning.

Sustainability and Innovation Trends

Sustainability is becoming a key focus area in the Rubber Processing Chemicals Market. Manufacturers are increasingly developing environmentally friendly and low-toxicity chemical solutions to reduce environmental impact and comply with stringent regulations. The shift toward green tires and sustainable rubber products is driving innovation in bio-based and eco-efficient processing chemicals.

Technological advancements in rubber compounding, automation, and digital manufacturing are further shaping market dynamics, enabling improved efficiency and consistent product quality.

Future Outlook

The future of the Rubber Processing Chemicals Market appears promising, supported by steady growth in tire and non-tire rubber applications, expanding industrial activities, and continuous innovation in rubber processing technologies. As industries demand higher performance, safety, and sustainability from rubber products, the role of specialized processing chemicals will become increasingly vital.

With ongoing advancements and rising global demand for durable and efficient rubber solutions, the Rubber Processing Chemicals Market is set to remain a crucial component of the global rubber industry value chain.

About Us:

Business Market Insights is a market research platform that provides subscription service for industry and company reports. Our research team has extensive professional expertise in domains such as Electronics & Semiconductor; Aerospace & Defense; Automotive & Transportation; Energy & Power; Healthcare; Manufacturing & Construction; Food & Beverages; Chemicals & Materials; and Technology, Media, & Telecommunications.

Contact us:

- If you have any questions about this report or would like further information, please contact us:

- Contact person: Ankit Mathur

- Email: sales@businessmarketinsights.com

- Phone: +16467917070

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness