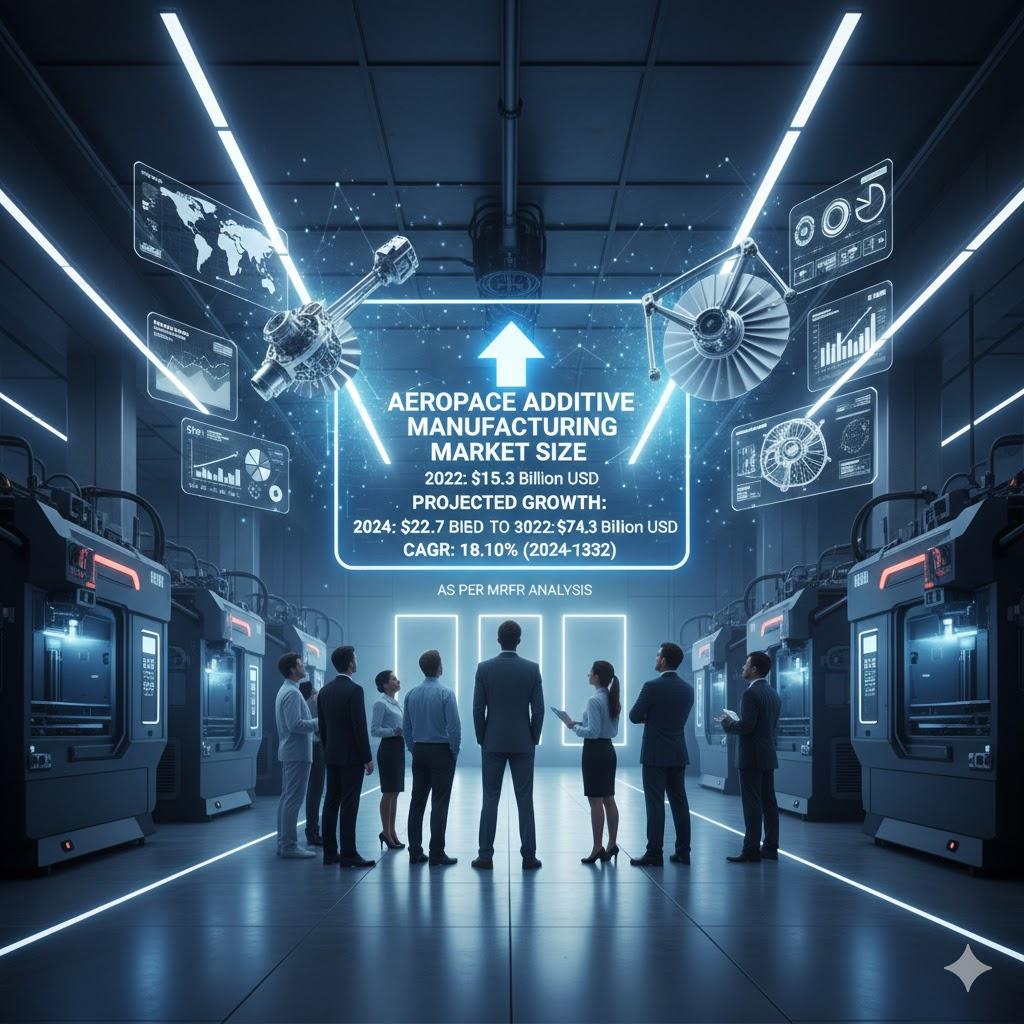

Aerospace Additive Manufacturing Market Outlook: Accelerating Innovation Across Aircraft and Space Systems

The global Aerospace Additive Manufacturing Market is entering an exciting new phase as aviation companies adopt 3D printing to support advanced engineering, faster production cycles, and improved performance. As competition intensifies, organizations increasingly rely on detailed industry insights available in the latest Aerospace Additive Manufacturing Market research report, which highlights the new opportunities shaping the future of aerospace innovation.

Introduction: A Technology Transforming Aviation

The aviation industry continues seeking ways to innovate faster, reduce cost, and deliver better-performing aircraft. Additive manufacturing in aviation plays a critical role in meeting these goals. This technology enables engineers to create complex shapes, reduce material waste, and produce lighter components. As a result, aerospace 3D printing has shifted from a niche tool to a mainstream production method across leading aircraft manufacturers.

Moreover, material advancements fuel the industry’s rapid growth. Metal additive manufacturing now supports materials suitable for engine environments, while high-performance polymers meet interior application standards. Together, these innovations expand the capabilities of 3D printing in aerospace engineering.

Market Growth Factors and Drivers

Several forces continue fueling momentum in this fast-growing market. These drivers illustrate why additive technologies remain vital to the future of aircraft manufacturing.

- Demand for Lightweight, High-Performance Structures

Reduced aircraft weight improves efficiency and flight range. Additive manufacturing enables lattice structures and optimized geometries.

- Fast Development and Prototyping

Additive methods shorten design cycles. Engineers test multiple variations quickly, improving decision-making.

- Enhanced Supply Chain Agility

Aerospace 3D printed components improve part availability and reduce reliance on traditional suppliers. This helps minimize disruptions.

- Digital Manufacturing Growth

The industrial 3D printing market aligns with digital transformation initiatives. Data-driven production improves consistency, reducing errors.

In addition, environmental goals push manufacturers toward greener production. Additive methods reduce waste by building only what is required.

Segmentation Analysis

Understanding the segments within the Aerospace Additive Manufacturing Market reveals where the most promising opportunities lie.

By Technology

- Metal Additive Manufacturing: Supports critical engine and structural applications.

- Polymer Additive Systems: Ideal for interiors and non-critical parts.

- Composite-Based Additive Methods: Offer strong, lightweight solutions for specialized components.

By Application

- Prototyping

Enhances design exploration and testing. - Tooling Production

Creates lightweight, customizable tools that accelerate assembly processes. - End-Use Component Manufacturing

A rapidly growing segment as more certified additive parts enter service.

By End User

- Commercial Aviation Companies

- Defense and Military Organizations

- Space Exploration and Satellite Firms

Each segment benefits from ongoing improvement in aerospace manufacturing technologies.

Regional Analysis

Adoption levels vary across regions, influenced by investment, infrastructure, and aerospace ecosystems.

North America

This region leads global adoption due to strong aerospace presence and continuous research investment. Many OEMs integrate metal additive manufacturing into their production lines.

Europe

Europe remains a leader in innovation, especially in material science and certification frameworks. Regional manufacturers actively incorporate 3D printing in aerospace engineering.

Asia-Pacific

Rising aviation demand and expanding defense budgets support increased adoption. Many regional players invest heavily in digital manufacturing capabilities.

Other Regions

Emerging markets implement additive methods for maintenance and repair, improving efficiency and reducing downtime.

Future Growth: Opportunities Ahead

The Aerospace Additive Manufacturing Market shows strong long-term potential as digital manufacturing continues expanding. Several opportunities will shape future growth:

- Advanced Software and AI Integration: Intelligent tools help optimize designs for performance and safety.

- New High-Performance Materials: Evolving alloys and polymers are widening additive manufacturing applications.

- On-Demand Global Production: Digital inventories support faster part delivery anywhere in the world.

- Space Industry Expansion: Lightweight, durable components created through additive methods boost space missions.

In addition, automated post-processing solutions will reduce operational complexity, making additive manufacturing more accessible to aerospace companies of all sizes.

Frequently Asked Questions

- Why is additive manufacturing beneficial for aircraft production?

It reduces material waste, improves design flexibility, and accelerates development timelines for both prototypes and functional components.

- What types of aircraft parts use 3D printing today?

Common examples include brackets, ducts, interior panels, engine components, and customized hardware created through metal and polymer technologies.

- How will additive manufacturing shape the future of aviation?

It will enable more efficient aircraft, faster production cycles, and expanded design possibilities that improve performance and safety.

Conclusion

The Aerospace Additive Manufacturing Market continues unlocking new opportunities as aviation companies integrate advanced 3D printing into their production strategies. With improved materials, digital workflows, and growing global adoption, additive manufacturing is set to play an even larger role in the next generation of aircraft design and manufacturing. As the industry evolves, companies embracing these innovations will lead the future of aerospace engineering.

Related Report:

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness